Product Catalog

Contact Information

Telephone:86-592-6108825

Mobile:86-18046209932

Email:2786761380@qq.com

Address: Building 103, Building Materials Park, Tongan District, Xiamen City

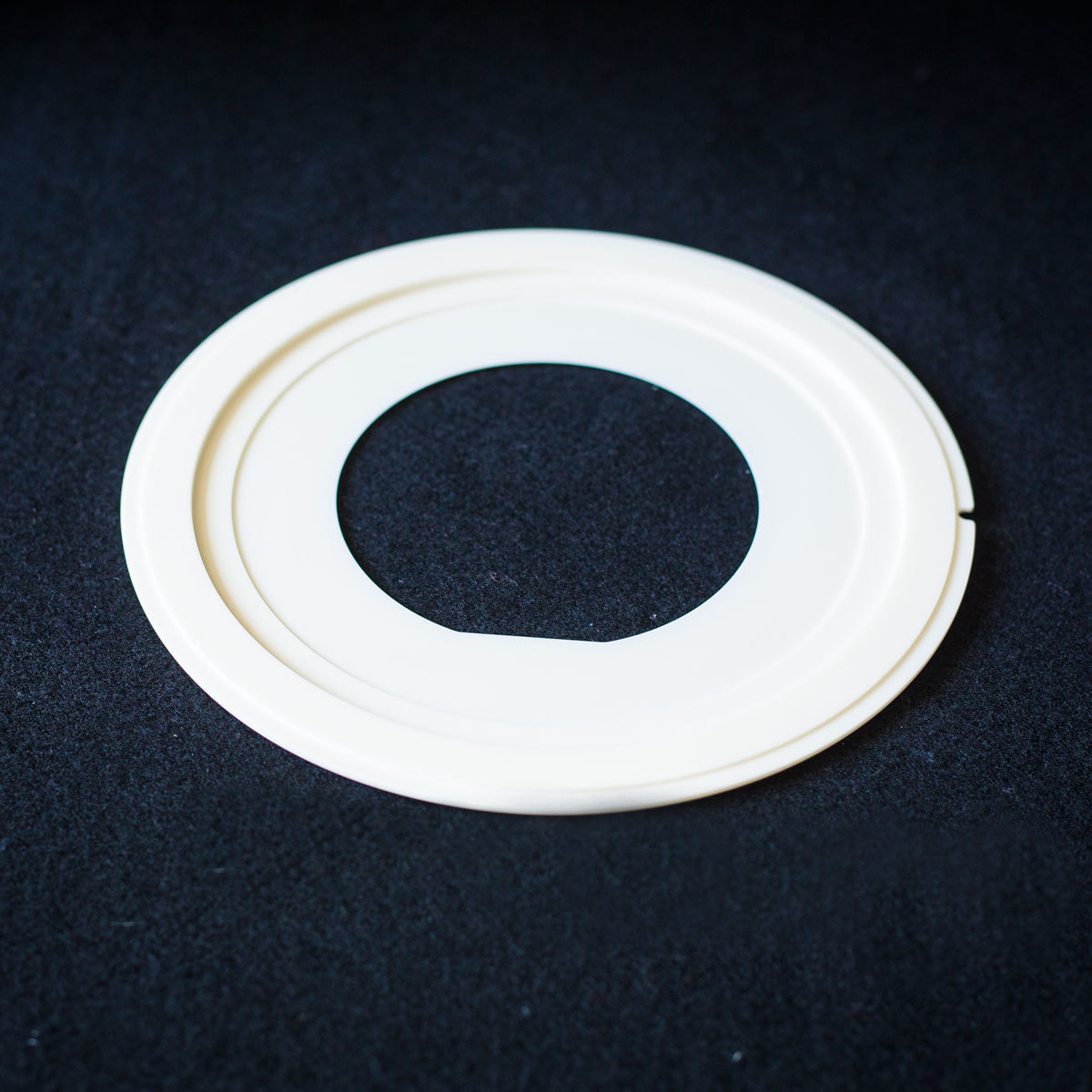

Vacuum sucker

Zirconia ceramics is a new type of high-tech ceramics. It has excellent characteristics such as high strength, high hardness, high temperature resistance, acid and alkali corrosion resistance, etc. It is an insulator at room temperature and has conductivity at high temperature. Zirconia has a melting point of 2715 ° C. The higher melting point and chemical inertness make zirconia a better refractory material. Zirconia ceramics have higher hardness and better wear resistance. The Mohs hardness of zirconia ceramics is about 8.5, which is very close to the Mohs hardness of sapphire 9, the Mohs hardness of tempered glass is 5.5, and the Mohs hardness of aluminum-magnesium alloy is 6.0. The Mohs hardness of Corning glass is 7. Zirconia ceramics have greater strength, although there is a big gap between toughness and some metals, but it is better than other ceramic materials. The thermal conductivity of zirconia is the lowest among common ceramic materials, and the thermal expansion coefficient is close to that of metal. Therefore, zirconia ceramics are suitable as structural ceramic materials.

Download information:

Keywords: alumina ceramics, talc porcelain, oxidation bowl textile ceramics

Classification:

Product Description

Ceramic material

oxidation error

machining accuracy

0.005mm

Product characteristics

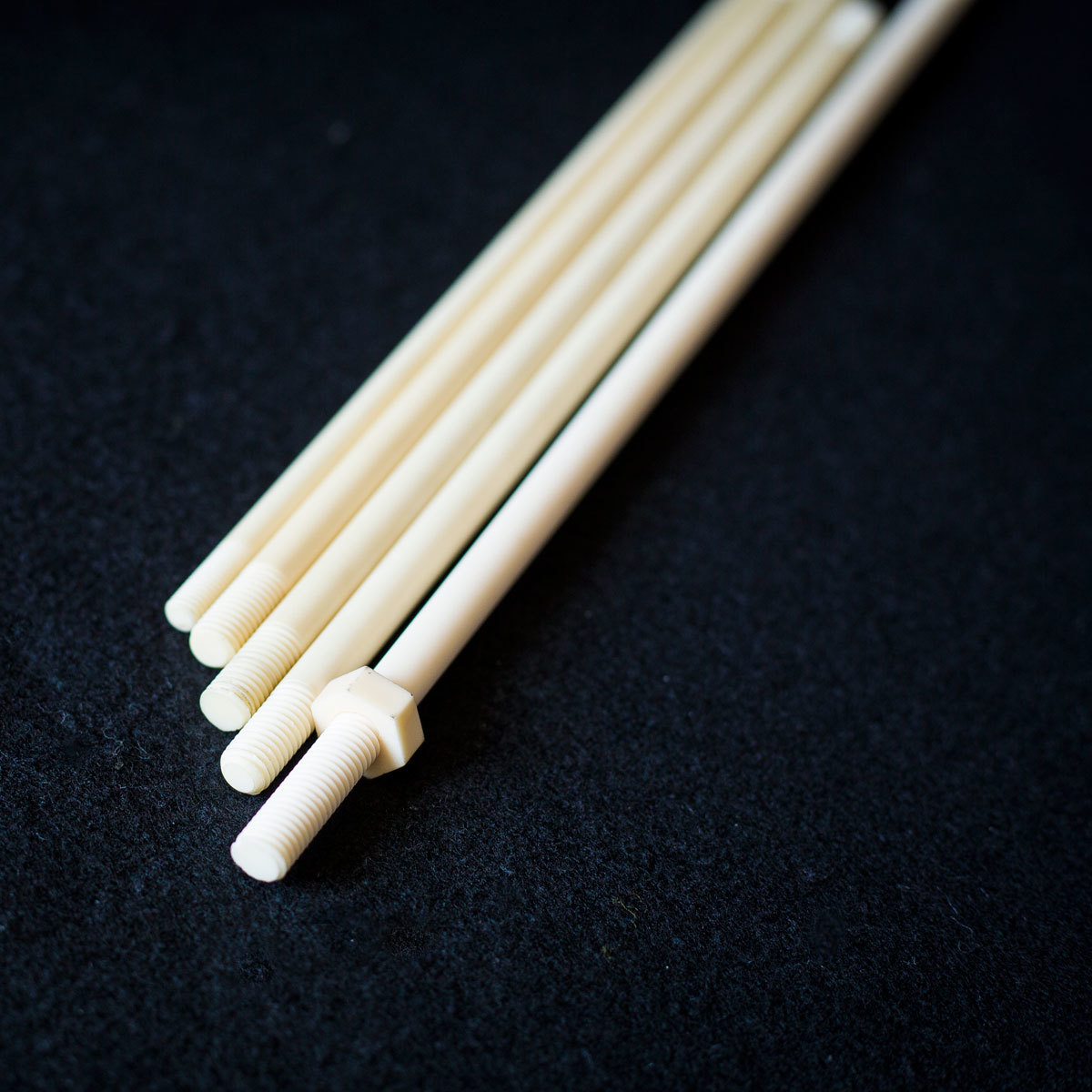

Wear resistance, high temperature resistance, high hardness, high strength, high toughness to provide color: white, black, beige

Custom processing

According to the drawings to map custom processing

machining accuracy

(1) Shaft: roundness 0.002mm, concentricity 0.002mm, finish Ra0.1;

(2) Hole: The minimum processing aperture is 0.2mm, and the depth can reach 6 mm (depending on the material);

(3) groove: minimum processing 0.1mm narrow groove, as well as various shapes of the groove;

(4) Plane: minimum processable thickness 0.1MM sheet, parallelism 0.001mm, measurement tolerance 0.001mm, smoothness Ra0.1;

(5) Thread: The smallest processable M2 internal thread has GB-7h precision, unlimited external thread size and GB-6g precision.

Material Introduction

Zirconia ceramics is a new type of high-tech ceramics. It has excellent characteristics such as high strength, high hardness, high temperature resistance, acid and alkali corrosion resistance, etc. It is an insulator at room temperature and has conductivity at high temperature.

Zirconia has a melting point of 2715 ° C. The higher melting point and chemical inertness make zirconia a better refractory material.

Zirconia ceramics have higher hardness and better wear resistance. The Mohs hardness of zirconia ceramics is about 8.5, which is very close to the Mohs hardness of sapphire 9, the Mohs hardness of tempered glass is 5.5, and the Mohs hardness of aluminum-magnesium alloy is 6.0. The Mohs hardness of Corning glass is 7.

Zirconia ceramics have greater strength, although there is a big gap between toughness and some metals, but it is better than other ceramic materials.

The thermal conductivity of zirconia is the lowest among common ceramic materials, and the thermal expansion coefficient is close to that of metal. Therefore, zirconia ceramics are suitable as structural ceramic materials.

Related Products

online message